The roofing industry is a highly-complicated, highly-technical division of construction. Many popular types of commercial and residential roofs are composed of metal. But, what kind of metal? What profile? What accessories are needed? Let us help you dive a little deeper.

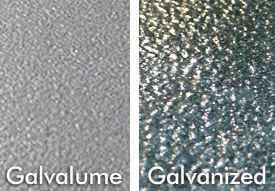

Steel is the most common type of metal used in roofing, due to its affordability and strong performance in most environments. Specifically, most steel we encounter daily, whether part of a roof, chair, car or even paper clips, is composed of galvanized steel, which is produced when pure steel is dipped or coated with molten zinc. This coat, first used in 1836, gives the steel an extra layer, protecting it from weather and rust, while still providing superior strength due to its steel interior. Another type of steel popular in roofing is galvalume steel, first used in 1972. This variation is coated in a mixture of molten zinc, aluminum, and silicon. The aluminum in the coating gives galvalume altered characteristics.

These two different types of steel have various pros and cons when compared to one another. Over the duration of ten years, galvanized will look better than galvalume, for its pure zinc layer has the ability to “self-heal” from small nicks and scratches. This process keeps the steel underneath protected from rust. Initially, galvanized steel looks pristine, but once the zinc layer wears down within 10 to 15 years, rust begins to quickly and exponentially spread. Between years 15 to 25, the rust will most likely saturate the entire panel. On the other hand, galvalume does not self-heal and will begin corroding immediately. Fortunately, the corrosion will not spread and will remain isolated due to its aluminum content, allowing for much more manageable responsive maintenance for the longevity of the roof’s lifespan.

When it comes to testing the raw properties of both metals in terms of longevity and weatherability, galvalume wins, with an estimated 40 years life-span compared to 25 years for galvanized steel. However, there are a couple of exceptions to keep in mind when choosing which steel to use for your roof.

- Brick and mortar walls will “kill” aluminum and, therefore, galvalume. If a structure has a brick and mortar wall, or any other “cementitious” material, any adjacent metal roofing cannot be composed of aluminum or galvalume. The best affordable alternative is galvanized steel, but the structure must be 1-2 miles from a coastline. Prevailing maritime wind direction should also be considered. Ultimately, cementitious-structured houses, in maritime environments, must be built with more expensive options like copper or stainless steel.

- Modern technology’s “Kynar Paint” usually guarantees 30+ years of rust-free performance when used in accordance with the manufacturer’s recommendations. 99% of steel panels have this paint finish nowadays. However, even with the paint, aluminum or galvalume should not be used around cementitious material, and galvanized steel should not be used in coastal or maritime environments

In conclusion, both types of steel have their advantages, disadvantages and exceptions. Ultimately, the decision boils down to what your roofing contractor recommends in your specific circumstance, what kind of material your building is made of, and what you, the customer, value most.

To receive an expert opinion from Bone Dry Roofing, give us a call today at 1-855-BONEDRY!

Sources:

https://www.galvanizing.org.uk/hot-dip-galvanizing/history-of-galvanizing/

https://www.roofingcalc.com/galvalume-vs-galvanized-steel-roofing/

https://www.masoncontractors.org/2012/05/11/masonry-wall-flashings/